Aerospace - Die machining

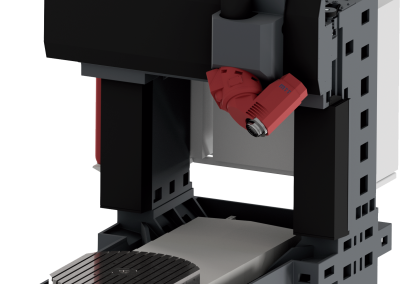

Precision and Performance: Revolutionary Machine Tools for Aerospace and die machining SectorsMeccanotecnica and MTT offer machine tools that comply with the high technical standards required by the aerospace and die machining sectors. These include both accurate dimensional and geometric precision, as well as excellent surface finishes, and the ability to work with materials such as titanium and nickel alloys.

All of this is made possible through the use of structures and bases that can contain vibrations and ensure excellent movement dynamics, heads and high-performance electrospindles designed by MTT, in addition to precise positioning systems and the best control technologies. In particular, the Twister line includes fully enclosed machines, with a movable crossbeam that allows for lighter loads to be moved, benefiting speeds and accelerations especially in semi-finishing and finishing operations of die machining; for larger parts, the Unika line can be used, which also has a movable crossbeam. The Harmonica line allows for 5-axis machining and easy management of sub-assemblies even in large components. Depending on the needs, it is possible to choose the combination of heads (mechanical or electrospindle) and work tables (rotating and tilting) that is most suitable for the complexity and type of components of interest to the customer.

For the most advanced engineering sector, which cannot accept compromises.