Oil & Gas - Series

Reliability first: Cutting-Edge Machine Tools for Complex Machining OperationsMeccanotecnica and MTT present a wide range of precision and reliable machine tools in their extensive portfolio.

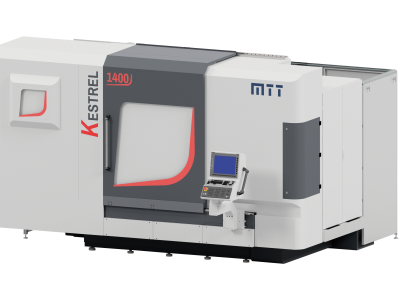

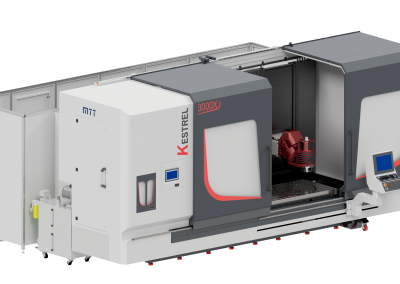

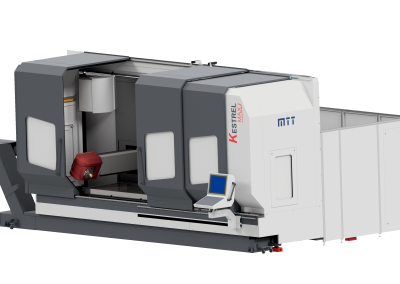

With the Kobra line of moving column machines, it is possible to perform highly detailed and complex machining operations, thanks to the availability of various spindle heads and compatible worktables. The tool magazine is located inside the main column, allowing tool changes to be made in any position, making the machine suitable for serial production. Additionally, the octagonal section ram body with hydrostatic bearings enables rapid feed rates of up to 40 m/min without compromising stability. The same line can be configured with 2 pendulum work zones, offering a total of 3+5 controlled axes. On the Kestrel line, there is an octagonal carriage centered on 4 roller recirculating monoguides and a highly efficient “box in the box” enclosure, along with continuous working heads (non-indexed). These machines, along with other machining centers offered in multiple configurations, can be combined together using the provided automation solutions to develop safe and efficient turnkey installations.

The Meccanotecnica Group is also capable of providing support in studying layout and work procedures that are most suitable for the customer’s needs, in order to optimize production lines.

Ready to tackle the challenges of sustainability in the energy and mechanical manufacturing sectors in general.