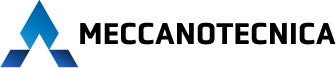

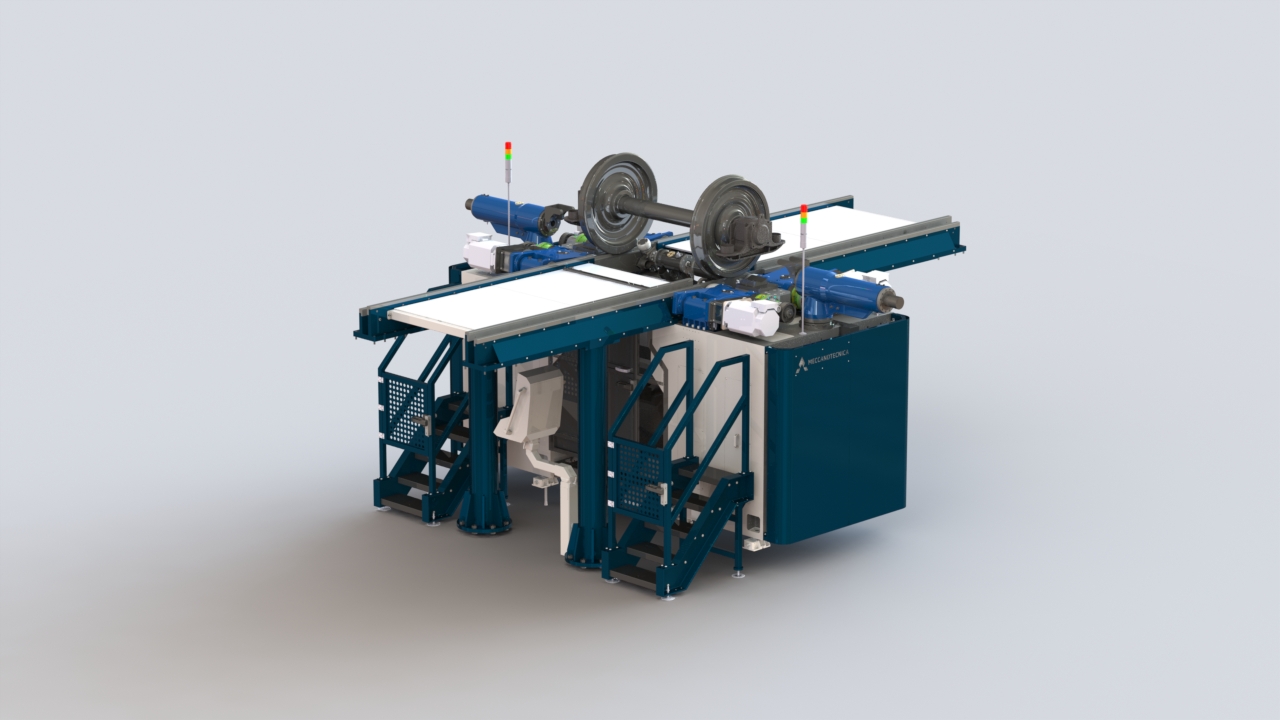

MCT TF40

Underfloor Wheel Lathe

Applications

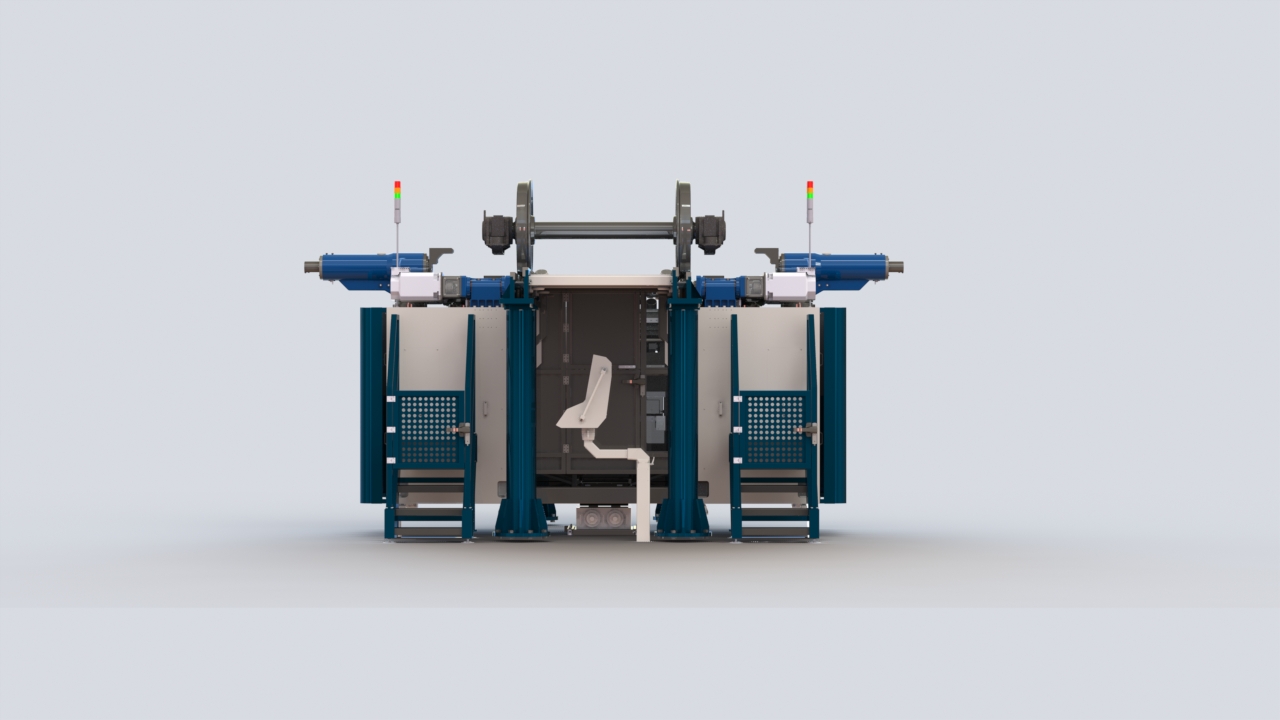

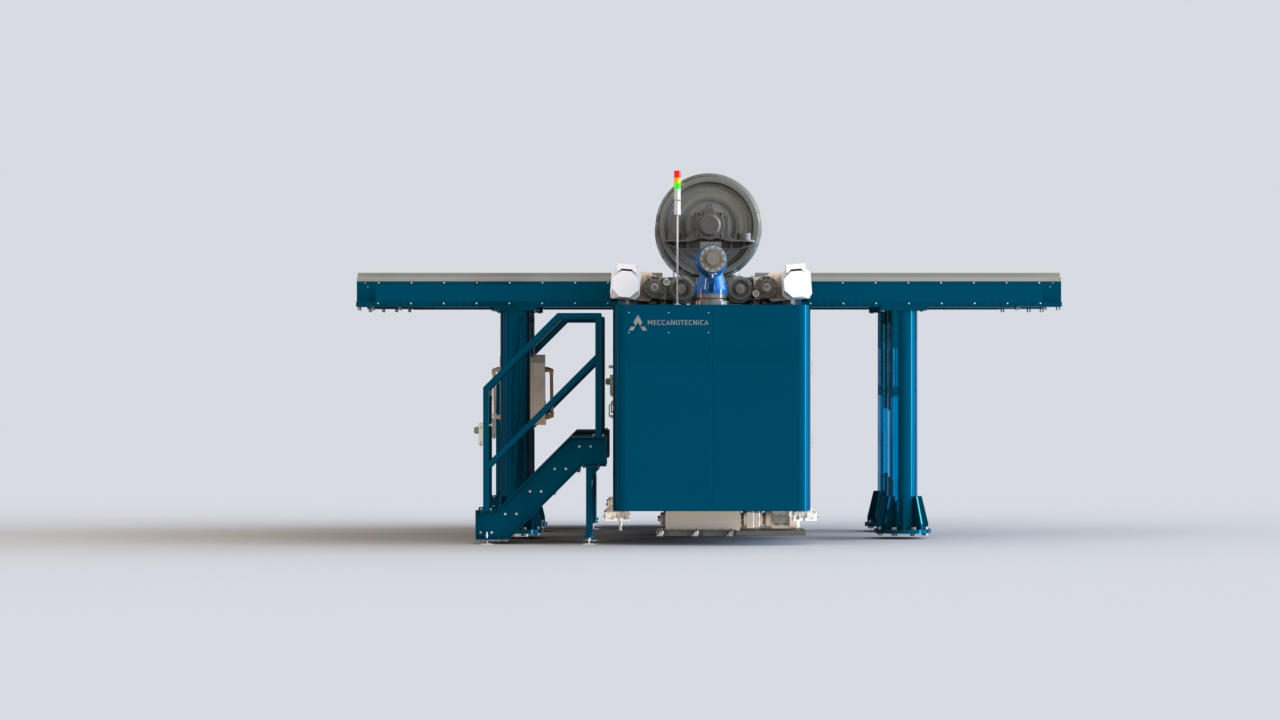

The brand new MCT TF40 underfloor lathe finds application in the reprofiling of railway wheels and brake disks mounted on wheels or on axles. The flexibility of this machine includes the capability to work on single wheelsets, bogies, entire wangons and locomotives used both in people and goods transport. Thanks to these characteristics, working procedures are optimized and simplified, improving efficiency.

Our TF40 is a dinamically rigid and reliable machine, customizable to requested specifications.

Technical specifications

| MACHINE SPECIFICATION | International System | Imperial System |

|---|---|---|

| Machine dimensions (L x W x H) | 6,5m x 5m x 2,4m | 21ft x 16ft x 8ft |

| Pit dimensions (L x W x H) | 10m x 6,1m x 2,4m | 33ft x 20ft x 8ft |

| Machine weight | 35.000 kg | 77,000 lb |

| Maximum power consumption | 140 kW | |

| Maximum axle load | 400 kN | |

| Minimum-maximum running circle diameter | 650÷1250 mm | 25.6÷49.2 inches |

| Minimum-maximum wheel thickness | 75÷140 mm | 3.0÷5.5 inches |

| Track gauge | European (1435 mm) | |

| Maximum tool removal | 10 sq mm | |

| Working diameter tolerance between the wheels of a wheelset | ≤0,15 mm | ≤0.006 inches |

| Working diameter between the wheels of a bogie | ≤0,30 mm | |

| Radial run-out | ≤0,1 mm | ≤0.004 inches |

| Maximum chip cross-section per support | 10 sq mm | 0.39 sq inches |

| Axial run-out on the internal faces of the wheels | ≤0,10 mm | |

| Profile processing precision | ≤0,15 mm | |

| Obtainable roughness (RA) | ≤1,6 µm | |

| Maximum spindle speed | 525 rpm | |

| Axis advancement X | 3 mt/min | |

| Axis advancement Z | 5 mt/min |

Optionals

- Brake disks machining

- Chip shredding and evacuation system

- Full electric execution

- Automatic lubrication

- Extra-European gauge

- Remote control and monitoring

- Database management

- Train release system without power supply

- Customized work cycles

- Operator trainings