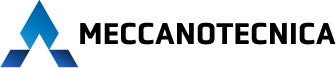

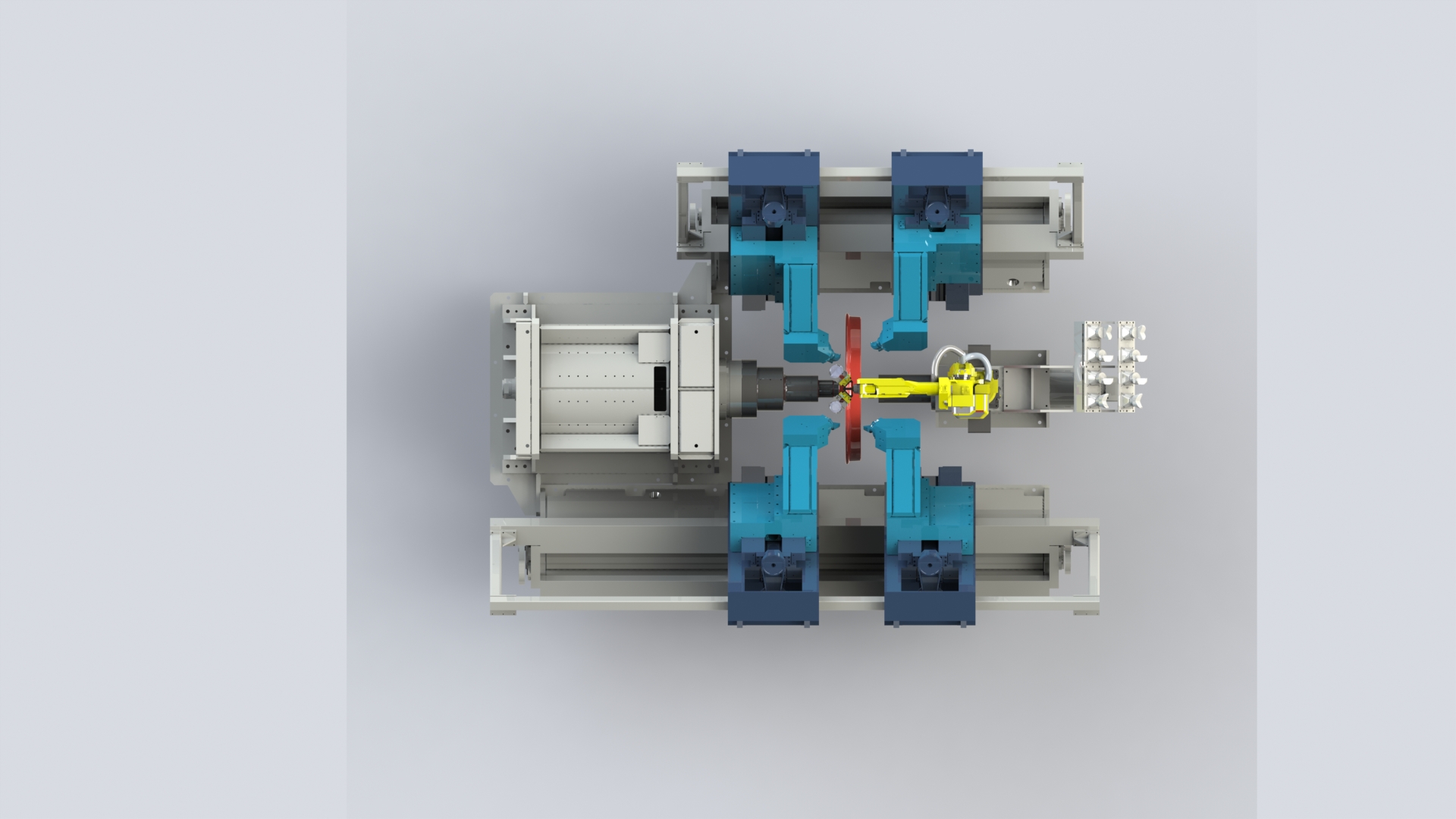

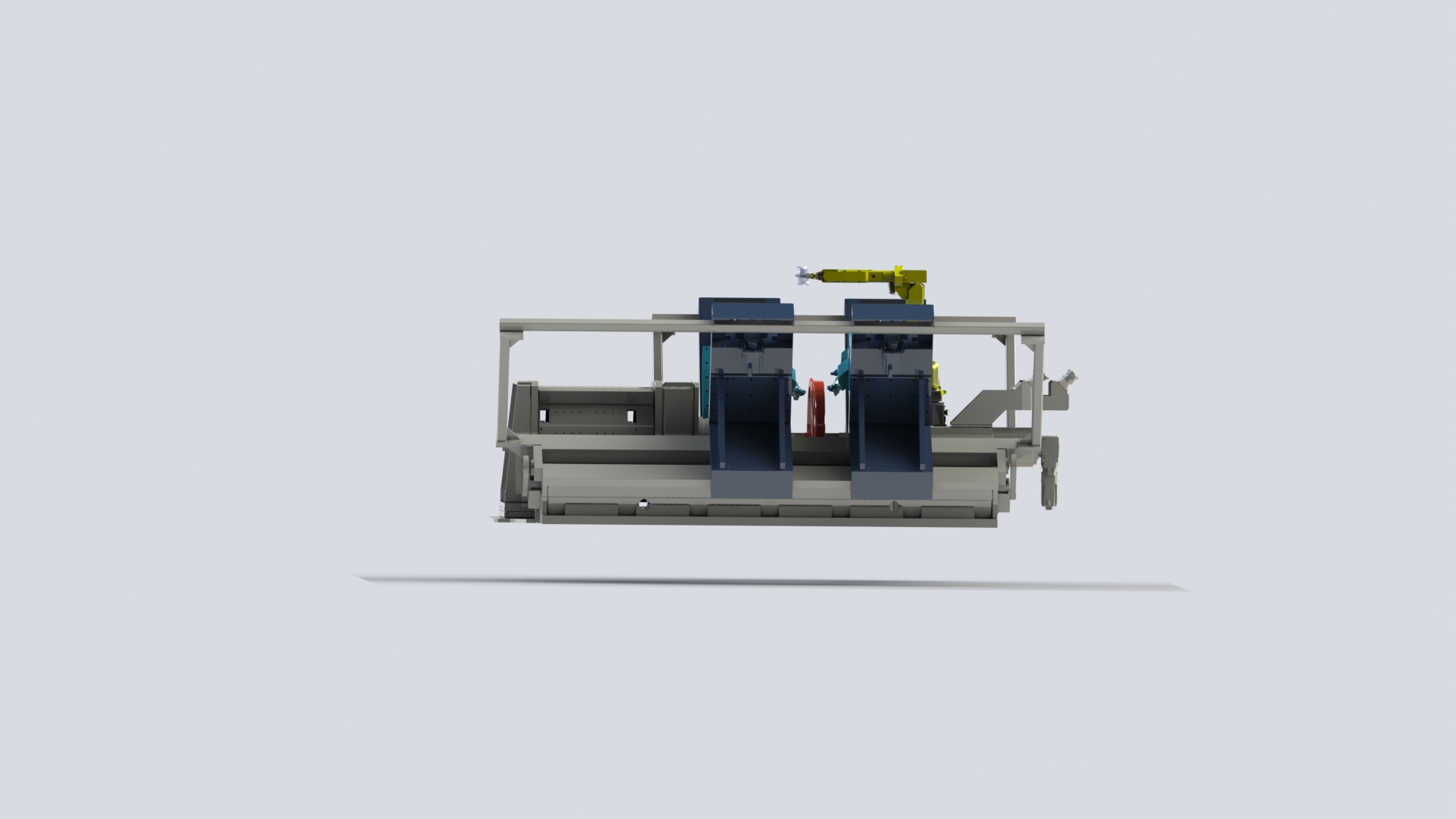

MCT TO4C

Special Multi-Carriage Lathe for Railway Solid Wheels

General characteristics

- Processing times reduced by up to 50%

- Better level of precision than actual machines

- Zero setup time (for most wheels)

- Simple foundation

- Quicker loading

- More safety in the clamping procedure

- Easy metal chip removal thanks to the wheel position

- Interface with local management system

- Authomated tool change with anthropomorphic robot

Applications

The innovative conception machine MCT TO4C refers to an equipment for machining railway wheels, for example, freight, passenger, motor, underground and high-speed wheels.

In particular, this equipment can be used to perform one or more mechanical machining operations, to remove material, both roughing and finishing, on a raw wheel to obtain a finished wheel with the technical characteristics (dimensional tolerances, surface finish, circularity of the profile, etc.) required by the particular application they will serve.

The solution patented by us for the processing of railway wheels, is suitable for use in the turn-key field for large automated systems, but it has also been designed as a stand-alone solution in combination with single and smaller portals / robots compared to an automatic line. This allows it to be used both for small quantities more efficiently, and for larger quantities by adding these lathes to an automated line.

Technical specifications

| MACHINE SPECIFICATION | International System | Imperial System |

|---|---|---|

| Machine dimensions (L x W x H) | 5m x 4m x 2,8m | 16ft x 13ft x 9ft |

| Machine weight | 35.0000 kg | 77,000 lb |

| Maximum power consumption | 150 kW | 150 kW |

| MACHINING and TOLERANCES | ||

| Minimum-maximum running circle diameter | 650÷1250 mm | 25.6÷49.2 inches |

| Minimum-maximum wheel thickness | 75÷150 mm | 3.0÷5.5 inches |

| Maximum chip cross-section per carriage | 8 sq mm | 0.3 sq inches |

| Working diameter tolerance | ≤0,05 mm | ≤0.002 inches |

| Tool storage | 8+ places | 8+ places |

| Tool change system | robotic arm | robotic arm |

Optionals

- Chip shredding and evacuation system

- Automatic tooling

- Automatic lubrication

- Remote control and monitoring

- Database management

- Operator trainings